Industrie 4.0#

Industrie 4.0 is the name of the fourth industrial revolution. The first three industrial revolutions did put a focus on mass production, and each of these revolutions did introduce significant changes into production. The first industrial revolution at that time did introduce mechanical machines. They increased the available working power significantly, and provided great support to human workers. The introduced additional steam- and water-powered workforce did significantly improve the production. The second industrial revolution was the electrification and the introduction of the conveyor belt, which enabled the modern assembly line. The resulting division of labor did greatly increase the efficiency of production plants and was the beginning of the modern mass production. This led to significantly better product availability and thus an increase in general living standards. The third industrial revolution was driven by automation technology - it started by replacing monotonous and repetitive steps in production with robots. PLC controllers did automate more and more production steps. This also had significant consequences for production. Not all of them were positive at that time. The automation did replace many jobs in production with machines. As a consequence, many workers lost their jobs during this phase. On the other hand, the automation again did significantly increase the efficiency of production, which did result again in cheaper prices for mass produced products, and also new jobs in the automation industry. The fourth industrial revolution, at the threshold of which we are located, addresses the end-to-end digitalization of manufacturing. It will of course also have impact on the mass-production. But in addition to the previous three revolutions, Industrie 4.0 will introduce additional, and much more revolutionary changes to production systems.

A story: Purchasing a car in an Industrie 4.0 world#

Today, the process of purchasing a factory new car consists usually of the configuration of the car, followed by a long waiting period. In this waiting time, the car is manufactured without involving the customer. Industrie 4.0 could change that. Imagine, that after ordering your car, you will be informed about the production steps. You want to see how your car is painted? Just activate the live stream when you are invited and follow its production. You want to change your order? The IT system of the manufacturer will tell you about the status of the production, about possible changes at the current time, and possible cost increases when changing parts of the car after production has started. The production backend will be able to match changes with orders of other customers, and therefore provide the best experience to all customers. But much more important, manufacturers will be able to tie customers much better to their brand compared to today. Need a customized order? No problem, in the Industrie 4.0 world, individual orders are produced at the same cost as mass produced goods, thanks to lot-size one production.

This example shows the limitation of todays automation equipment. Automation controllers, for example PLC controllers, execute repetitive process steps and provide automation for rarely changing process steps. Automation devices support repetition of tasks with highest precision. This yields high-quality mass production that, as soon as it is setup, produces large numbers of similar products at cheap prices. Existing automation technology however only has limited support for changeable production. The process of setting up an automated production or changing it is labor intense, time consuming, and therefore expensive. Moreover, the required time for changing a mass production cannot always be predicted. The reason for this are side effects: Today, manufacturing processes are very complex, and consist of a large number of dependent production steps. The resulting processes are very complex. PLC controllers that control process steps exchange data through field bus systems. Changes in one process step therefore quickly yield unwanted effects in other process steps. Similar to changes in complex software systems, changes in automation processes therefore yield side-effects that cause unforeseen errors that need to be fixed before the production can be re-started.

Implementing a changeable production requires more significant changes than those that were required for adopting the previous industrial revolution. Industrie 4.0 is not only realized by a new device, it will require a new architecture for manufacturing and production plants. Eclipse BaSyx supports the implementation of these architecture changes. The following pages in this section will outline the most important concepts of the fourth industrial revolution, and of the BaSyx architecture.

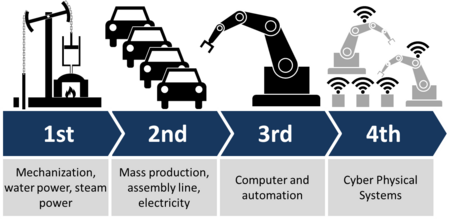

Four Industrial revolutions#

Four industrial revolutions - by Christoph Roser at AllAboutLean.com#

Industrie 4.0 is the fourth industrial revolution:

The first industrial revolution did happen at the end of the 18th century. The introduction of water and steam powered machines did trigger this industrial revolution. With their introduction, the work power of human workers was complemented by that of machines. This enabled a more efficient production.

The second industrial revolution was based on the principle of the division of labor. Electricity and the conveyor belt enabled the division of labor, which was the key to the modern mass-production. Many workers that did work on the conveyor belt had to perform repetitive tasks for each product with a defined frequency to ensure constant production. While this was the foundation for the availability of cheap, mass-produced goods, it was also a long-term synonym for working in a production environment.

The third industrial revolution was the automation of repetitive tasks. This revolution was based on the availability of electronics and IT. More and more simple, repetitive production steps were automated with e.g. robots. Programmable Logic Controllers (PLC) enabled the automation of work cells, production lines, and complete factories. Machines did take over more and more production tasks from human workers, and over time were increasingly substituting the human workers in factories.

Industrie 4.0 is the fourth industrial revolution. It is based on the end-to-end digitalization and end-to-end networking of production. By connecting formerly unconnected entities of production facilities, production is not only becoming more efficient, but also new business models become possible. It changes the architecture of production processes and introduces new, groundbreaking concepts to production systems. The integration of IT technology into production systems enable much more flexible and adaptive production systems that react quickly to market changes.

The first three industrial revolutions did focus on the improvement of production efficiency, and optimized the production towards mass production. Industrie 4.0 is different in this regard. The reduction of the per-unit production cost is still a major aspect of the Industrie 4.0. However, this does not only aim at mass production, but puts a focus in particular on the efficient production on small lot sizes. The mass production of products with lot-size 1 has become a synonym for Industrie 4.0. Behind this is the fact that most production lines today are able to deliver high quality at low production cost for large product quantities. Changing markets, complex supply chains and the demand for individualization however is creating new market demands. Customers are requesting smaller lot-sizes or even individualized products. Either for consumer goods, or for the creation of specialized products in low-volume markets. The ability to support these low-volume markets in the future with an efficient, and changeable production will be a competitive advantage in the near future.

Industrie 4.0 challenges#

Industrie 4.0 is however not only driven by the availability of new technology, but also by the need to adapt to changes in markets and in the society. The fourth industrial revolution therefore targets the following major changes to production:

Increase of efficiency, and decrease of downtime: A plant earns money if it is producing, and looses money as long as it stands still. Major car manufacturers are suffering from losses of about 5000 Euros per minute if a production line is stopped. Therefore, production id continuously optimized for high up-times. Industrie 4.0 improves the up-times of plants with improved predictive maintenance capabilities that are supported by the end-to-end communication and the direct access to sensor data that can be combined, evaluated, and used for predicting down times. Intelligent scheduling systems will optimize maintenance activities to reduce down times. Industrie 4.0 machines may also provide real-time information regarding the availability of spare parts. This information may be used by maintenance managers to manage the stock of spare parts and further improve machine availability. Last but not least, virtual testing and integration of process changes, and new, as well as changed machines can further reduce down times in case of process, product, and production changes.

Increased changeability: Markets are changing. Supply chains become more complex, and customers demand new product releases more frequently. This requires not only the product owners to change their production processes, but also all suppliers must adapt due to the often used customized product parts. Today, production lines are very efficient when producing large product quantities, but require high efforts for changes. Smaller lot sizes, e.g. 20 pieces of an adapted work piece, often cannot be produced. This limits product availability and increases cost. Industrie 4.0 propagates changeable manufacturing lines that can adapt to unforsen changes, and that therefore can be changed to support new manufacturing demands.

Automated documentation: Efficiency also extends to after-sales. If a major defect is detected after the sales of a safety-relevant product, e.g. a car, after sales, this product must be called back for maintenance. As production processes are complex, more and more commissioners request a per-unit documentation that covers all production steps. Digital twins as digital representations of machines, processes, and products can provide this kind of documentation. A digital twin may follow a product through the production process, and receive, and store all quality data in a structured manner. This machine-readable documentation covers all relevant production steps, e.g. the force that was used to tighten a screw, and the supplier of all parts of a work piece. Especially smaller companies without a digital manufacturing process face challenges when they need to implement this kind of documentation, and have the fear that they are not able to comply with future requirements.

Better process understanding: The gap between the IT and shopfloor machines often causes a lack of understanding of manufacturing processes. Smaller production companies often do not know the bottlenecks in their processes and have no data to decide whether a new order can be taken and be fulfilled until the requested deadline.

New business models: Industrie 4.0 also supports new data driven business models. Predictive maintenance, the creation of digital twins, and data based business is not the core competence of automation companies. This offers numerous possibilities for value creation to new companies that are not from the automation domain.

The Industrie 4.0 vision#

Industrie 4.0 therefore is the vision of a flexible production. In the future, think tanks could create new products. For manufacturing, they order capacities in changeable Industrie 4.0 production environments to produce their products at a similar price of mass produced products. Due to Industrie 4.0, the changing times that drive the price for small lot sizes will become less important. The think tank uses manufacturing plants as manufacturing providers - this is called production as a Service (PaaS). For this vision to become true, the technical foundation needs to be created. Eclipse BaSyx provides an open-source Industrie 4.0 middleware, and middleware components. This is a toolkit to enable the creation of tailored Industrie 4.0 solutions and products. Furthermore, Industrie 4.0 requires the harmonization of communication and models. For the think tank of our example to be able to use PaaS, the description of manufacturing steps and required quality must be harmonized. Machines must be able to decide whether a job can be taken, and whether the available production lines are able to fulfill the request. The enabling of numerous new products therefore requires a standardization in production steps and their description that does not limit the possible products to-be manufactured. This is another major challenge of Industrie 4.0.

Eclipse BaSyx provides the necessary base-technology as open-source software components to support developers in implementing Industrie 4.0 concepts in their production systems, as well as to create free and commercial Industrie 4.0 solutions. Ready-to-use software components provide the foundation of an infrastructure for Industrie 4.0. Defined interfaces ensure an open platform that enables the integration of new technology into the BaSys 4.0 ecosystem. Our SDK tools enable the development of applications, the integration of devices, and the development of new middleware components.

Even those that compete with our solutions :)